1,277,680 P.38s were produced during WWII: 617,585 by Walther in Zella-Mehlis 372,875 by Mauser in Oberndorf 287,220 by Spreewerk Grottau.

Pistols were produced in blocks of 10,000 consecutively numbered pistols, with each block having a consecutive letter suffix, to conceal production volume. To conceal manufacturer identities, each wartime manufacturer used a letter code: ac (Walther) byf (Mauser), and cyq (Spreewerk), followed by the date (e.g.: ac44: Walther 1944 production). ĭuring WWII, the P.38 was produced by three separate manufacturers: Walther, Mauser, and Spreewerk. The transition from HP to the mechanically-identical P.38-marked pistols took place 1939-1940. The designation P.38 indicates Wehrmacht adoption in 1938, although the exact date is unknown. Early production included a Swedish contract.

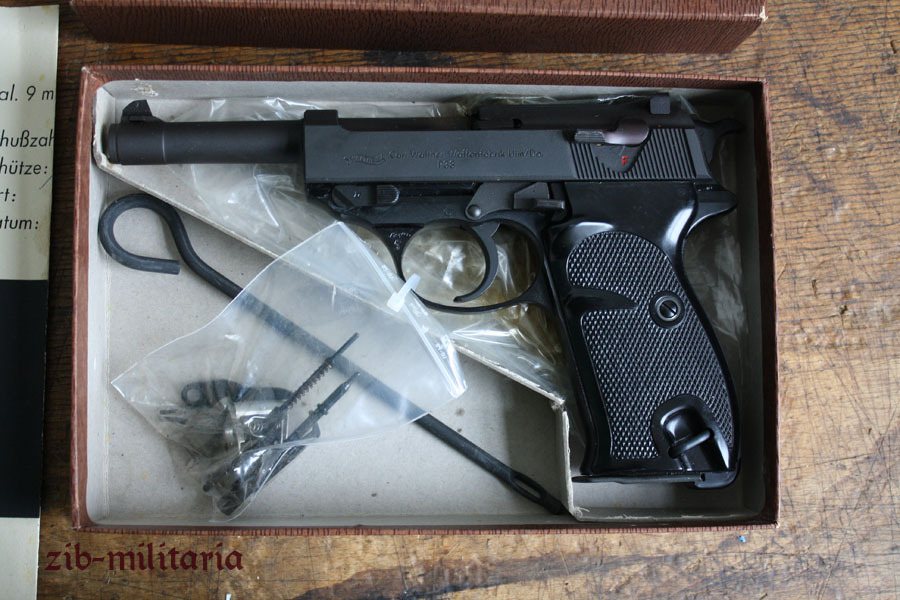

Initial development of the pistol took place 1937-1939, culminating in the first model, designated Model HP or Heerespistole ("army pistol"), which had several variants as engineering changes were made. The Walther P.38 was in production from 1939 to 1945. The hinged locking piece assisted breechblock design provides good accuracy due to the in-line travel of the barrel and slide. Two recoil springs on either side of the frame and below the slide, having been compressed by the slide's rearward movement, drive the slide forward, stripping a new round from the magazine, driving it into the breech and re-engaging the barrel ending its return travel with a fresh round chambered, hammer cocked and ready to repeat the process. Unlike most autopistols which eject empty cases to the right, the Walther P38 ejects empty cases to the left. The slide continues its rearward movement on the frame, ejecting the spent case and cocking the hammer before reaching the end of travel. When the pistol is fired, the barrel and slide recoil together, until the hinged locking piece drives down, disengaging the slide and arresting further rearward movement of the barrel. The moving-barrel mechanism is actuated by a wedge-shaped hinged locking piece underneath the breech. P38 made by Mauser, coded "byf 44" with matching presstoff and leather holster Besides a DA/SA trigger design similar to that of the earlier Walther PPKs the P38 features a visible and tactile loaded chamber indicator in the form of a metal rod that protrudes from the rear of the slide when a round is chambered. The firing mechanism extracts and ejects the first spent round, cocks the hammer, and chambers a fresh round for single-action operation with each subsequent shot – all features found in many modern day handguns. Pulling the trigger cocks the hammer before firing the first shot with double-action operation. The lever can stay on "safe", or if returned to "fire", the weapon remains safely "ready" with a long, double-action trigger pull for the first shot. The shooter could chamber a round, use the safety- decocking lever to safely lower the hammer without firing the round, and carry the weapon with a round chambered. The P38 was the first locked-breech pistol to use a double-action/single-action (DA/SA) trigger (the earlier double-action PPK was an unlocked blowback design, but the more powerful 9×19mm Parabellum round used in the P38 mandated a locked breech design). The P.38 was a cutting edge semi-automatic pistol design, which introduced technical features still used today in current commercial and military semi-automatic pistols, including the Beretta 92FS and its M9 sub-variant adopted by the United States military.

0 kommentar(er)

0 kommentar(er)